Precision Military Spec Parts CNC Machining

Expert Defense and Military Machining Capabilities

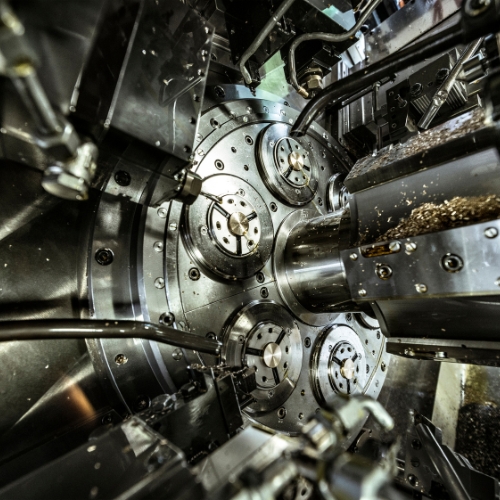

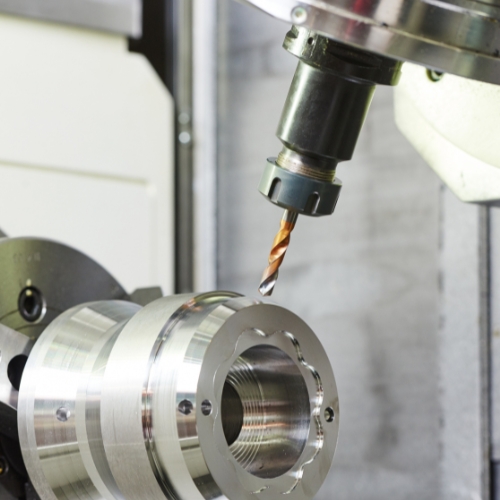

The military is one of those crucial sectors where there is close to zero tolerance for any flaws in its products, as they are used in mission-critical applications. While CNC machined parts are favored by many manufacturers across industries, the military sector has different specifications for the parts or components they need to machine or fabricate. Thus, military spec parts machining is a specialized segment among fabricators and CNC machining service providers. Princeton Industrial offers defense/military spec parts machining services, thanks to our advanced machines and diverse capabilities. Our advanced multi-axis machines enable us to perform more than one function at a time and are capable of mass production with consistent precision and tight tolerances.

Defense and Military Machining Capabilities

Contributing to the military service of our country is a matter of great pride and satisfaction for us. We offer custom mil spec parts that are made from Defense Federal Acquisition Regulation Supplement (DFARS) compliant materials and follow the required industry standards. We offer tolerance as tight as +/- 0.001 inches or as required for the application. Here are our defense/military spec parts machining capabilities:

Common Materials Used for Defense/Military Spec Parts Machining

At Princeton Industrial, we use robust metals such as titanium, brass, copper, stainless steel, aluminum, and alloys to make the tough weaponry parts that any military needs. This sector also requires nuts, screws, bolts, and so on which are just as strong. In fact, some parts are also made of tough and resistant plastic such as PVC, Delrin, and more. We have in-house tooling capabilities for all the metals, alloys, and plastics. Here are some of the most common DFARS materials we regularly work with to make military spec machined parts.

Titanium

This metal offers an excellent weight-to-strength ratio and mechanical durability to a part or product. We have a skilled workforce for machining titanium, which ensures the right speed, feed rates, and precision.

Aluminum

We often use tool grinding for aluminum, which is commonly used in shafts, gears, and even some aircraft components. Aluminum is lightweight and yet

Stainless Steel

Stainless steel is robust and corrosion-resistant and is commonly used in various parts required in the defense sector. We use various grades of steel, most of which are quite easy to machine.

Plastics

We use several types of plastics such as Delrin, PVC, Teflon, PTFE, and more. Plastics are commonly used in making certain components of hardware, aircraft parts, circuit enclosures, and so on. We are capable of achieving tight tolerances with plastics too. We help our clients choose the right type of plastic which can sustain the harsh environment in this sector.

Alloys

We combine metals such as brass, copper, and many others in the right proportion to enhance the physical and structural properties of the main metal. This enhances the hardness and strength of the product, while also improving its flexibility and bending capacity.

Why Partner with Princeton Industrial Products, Inc. for Your Defense/Military Spec Parts Machining

Customized Solutions

We take the time to understand your unique needs, ensuring the final product aligns perfectly with your requirements.

Experienced Team

With over 35 years of industry experience, our team handles even the most challenging projects with precision and expertise.

Advanced Technology

Utilizing the latest machinery and equipment, we guarantee accuracy and precision in every job we undertake.

Commitment to Quality

Our robust quality management system ensures all parts meet the highest industry standards.

Applications of Defense/Military Spec Machined Parts

As mentioned, we offer military spec parts machining services for a variety of parts. Here are some of them:

- Plates

- Tubes

- Screws

- Nuts

- Bolts

- Shafts

- Aircraft Parts

- Bearings

- Mechanisms

- Heat Sinks

- Bushings

- Pins

- Sliders

- Retainers

- Terminals

- Sleeves

- Cams

- Buttons

- Outer Guides

- Threaded Bushings

- Flanges

- Carriers

- Cones

- Pistons

- Connectors

- Nozzles

- Keys

- Plungers

- Safety Brakes

- Valve Stems

- Rivets

- Barrels

- Sensors

- Dials

- Castings

- End Plugs