Recreational Vehicles and Automotive Machining

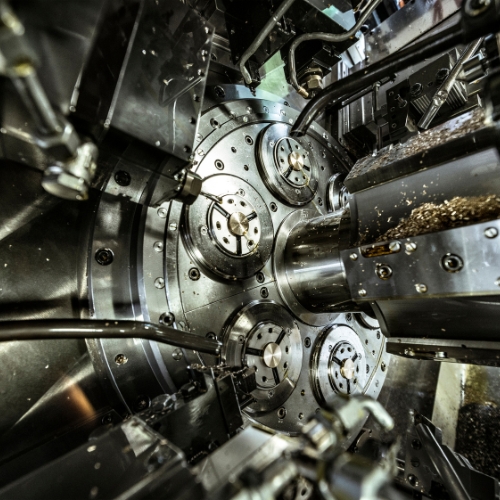

Precision CNC Machined Parts for the Automotive Industry

The automotive industry has evolved over the years, and vehicles have advanced in terms of technology and automation. The number of automotive parts with complex designs and integrated circuits has increased, and this is expected to rise in the future. This large volume of precision-machined parts can be achieved through automotive CNC machining. At the same time, it is crucial that all the parts are the same and flawless, and this is where automotive OEMs can rely on CNC machining. Princeton Industrial offers precision machined parts for the automotive industry. We achieve this through our metal and plastics part machining capabilities combined with vast industry experience.

CNC Automotive Machining Capabilities

Princeton Industrial is one of the trusted names in the automotive industry for plastic machined parts. Our following automotive products machining capabilities along with excellent services have earned us plenty of satisfied clients in this segment.

Common Materials Used for Automotive Machining

At Princeton Industrial, we work with both metals and plastics to create automotive CNC machined parts.

Metals We Use

Aluminum

This robust, durable yet lightweight metal is widely used in the automotive sector. We use aluminum types and alloys based on each requirement and the level of strength and hardness required. We have specialized cutting tools to machine this durable metal.

Stainless Steel

We use various types of stainless steel as it is machinable, robust, non-magnetic, and corrosion-resistant. We use Swiss machining, turning, and automated multiple-axis machines to make these parts. We have in-house tooling capabilities for the same.

Alloys

Various metals are combined to get the best output in terms of robustness, flexibility, and other physical and chemical properties required to make a part. An alloy enhances the properties of the original metal. We use aluminum as well as steel alloys.

Plastics We Use

Delrin

This is often used in bushings and gears among other automotive components. We use CNC milling, turning, and Swiss machining for Delrin components. Delrin is a plastic from the acetal family that provides strength, dimensional stability, friction resistance, and endurance for the part.

Nylon

We use CNC turning and Swiss machining for Nylon, and this plastic helps achieve tight tolerances. It can withstand high temperatures and is friction-resistant. It is commonly used to make bearings, bushings, and gears.

Teflon

Teflon, or PTFE, has high endurance and impact strength. It is resistant to frictional heat, radiation, and chemicals. We often use Swiss machining and CNC turning machines for Teflon.

Why Partner with Princeton Industrial Products, Inc.

Over the years, we have developed expertise in automotive parts machining, which is one of our key services. There are several reasons why automotive part manufacturers and OEMs may want to partner with us. Here are some of them:

Customized Solutions

We take the time to understand your unique needs, ensuring the final product aligns perfectly with your requirements.

Experienced Team

With over 35 years of industry experience, our team handles even the most challenging projects with precision and expertise.

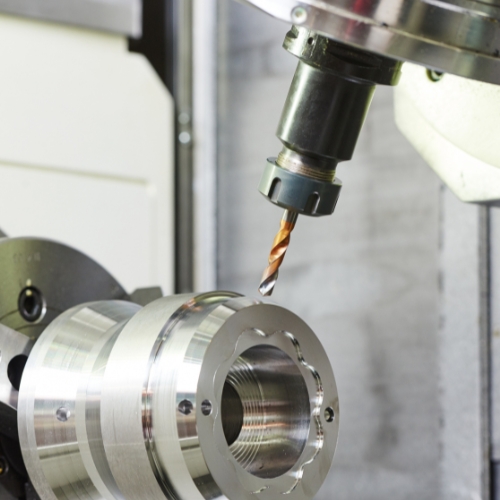

Advanced Technology

Utilizing the latest machinery and equipment, we guarantee accuracy and precision in every job we undertake.

Commitment to Quality

Our robust quality management system ensures all parts meet the highest industry standards.

Request Your Free Quote Below

Automotive Machining Applications

As mentioned, we are reliable partners for automotive industry leaders across the US. We have had the opportunity to work with top players and specialize in the fabrication of complex parts. Here are some of the application areas of our machining services in the automotive industry:

- Bushings

- Valve Retainers

- End-Use Parts

- Engine Parts

- Gearboxes

- Vintage Car Components

- Carburetor Enclosure Components

- Structural and Body Components