Quality Assurance For All Your Precision Machined Components

Princeton is Committed to Quality and Continual Improvement

Quality assurance is a methodology that ensures if the product meets the service level or agreed requirements in terms of structural and functional accuracy. This increases efficiency and productivity and develops a zero-tolerance policy for errors. Since errors can be spotted in the initial stages, it also helps reduce costs and downtime. Princeton Industrial has a dedicated quality assurance department which documents every detail of the errors identified and the steps taken for improvement or rectification. Documentation is an extremely important part of QA, and it has served as reference material for preventing future errors.

Princeton’s Holistic Approach Towards Quality Assurance

Princeton is ISO 9001:2015 certified, and this is a testimony to the company’s efforts to offer the best quality in terms of services, machined parts, and more. This has increased our credibility. We stick to industry standards when choosing materials, fabrication processes, and the types of CNC machines. We are capable of accurately producing parts or products with the tightest tolerances and complex designs. Here are some pointers which reflect how QA covers all aspects of our business.

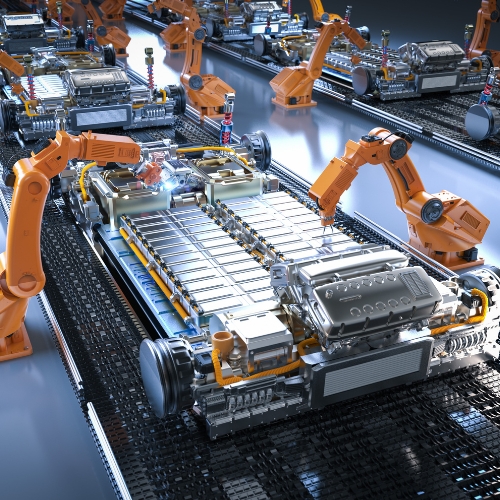

- Since we are a quality-focused organization, we significantly invest in good-quality machines and equipment with advanced features.

- We train our employees to focus on the quality aspect, which becomes ingrained in their work patterns.

- We also invest in research and development which fosters innovation and continual improvement.

- All our measurement instruments such as gages, optical systems, and so on are well calibrated, and their accuracy is checked periodically.

- We have strict testing procedures in place for each product and implement both manual and automated testing methods.

- Final inspection/testing is done before any product is shipped out.

- All of this helps us develop the best products for our clients and with a reduced time to market. Our prototypes serve as reference points for developing new versions of products with enhanced functionality.

To sum it up, our quality assurance process starts the moment we receive an order. It is implemented from thereon in the bill of materials, requirement gathering, product design, client meetings, approvals and documentation, part procurement, vendor validation, all stages of manufacturing, testing, packaging, customer service, and delivery. This is applicable for prototyping, low volume, and high volume production runs. If you have any questions regarding the quality assurance process we follow, you can contact us via phone or email.

Industries We Serve

We proudly serve a diverse range of industries, including

- Electronics

- Construction

- Military

- Oil & Gas

- Pharmaceutical

Why Partner with Princeton Industrial Products, Inc. for Your Precision Machined Components

Customized Solutions

We take the time to understand your unique needs, ensuring the final product aligns perfectly with your requirements.

Experienced Team

With over 35 years of industry experience, our team handles even the most challenging projects with precision and expertise.

Advanced Technology

Utilizing the latest machinery and equipment, we guarantee accuracy and precision in every job we undertake.

Commitment to Quality

Our robust quality management system ensures all parts meet the highest industry standards.