High-Quality Screw Machine Products

Expert Screw Machining Services

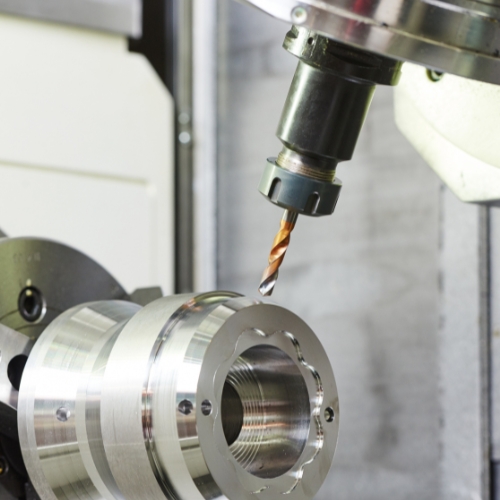

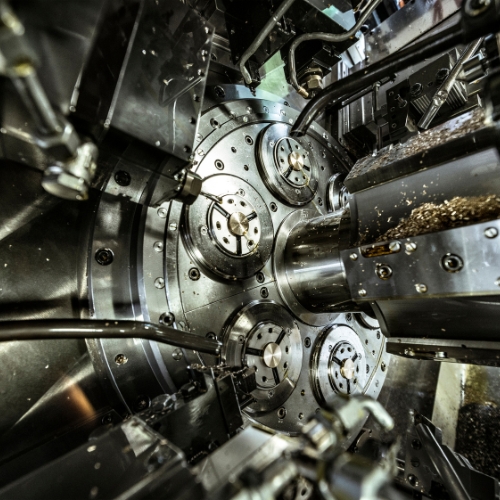

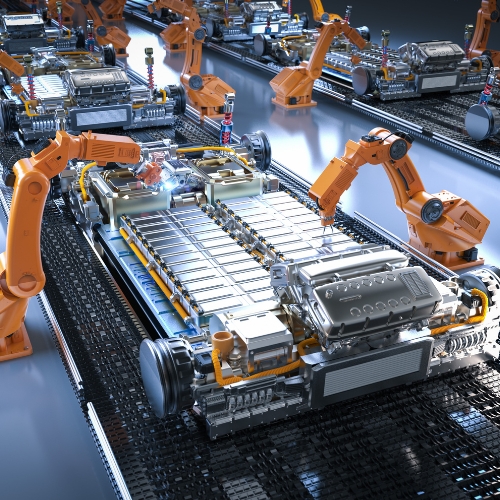

Our diverse automatic screw machine department enables us to manufacture very precise parts in large production volumes in the most efficient manner possible. These single and multi-spindle machines are equipped with special attachments that enable us to perform many types of secondary operations right on the machine, thus eliminating the need for additional processes. All this translates to cost reductions for our customers without sacrificing quality, consistency, or on-time delivery. Contact us today to get an instant quote.

Screws are commonly made of stainless steel; however, they are also made of other metals such as brass, aluminum, and more. Screw machining involves various CNC lathe techniques to turn metals into screws of the required shapes and dimensions. Princeton Industrial offers screw materials in metals—common as well as exotic ones—as well as plastic.

Screw Machining Capabilities

Here are some important features of our screw machining capabilities

Tolerances

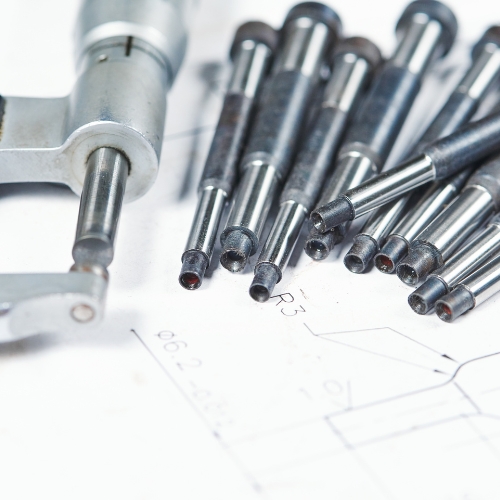

.0002" with a 32 micro-inch finish or better

Typical Annual Volumes

1 prototype up to several million pieces annually, depending on product complexity, application, and use.

Advanced Technology

Utilizing the latest machinery and equipment, we guarantee accuracy and precision in every job we undertake.

Quality Assurance

- MIL-I-45208A (Military Specification Inspection System)

- ISO 9001:2015

- JIT – Just in Time

- KAN BAN

- LEAN

- ESI

Materials Machined (Various Grades)

- Common Metals: Aluminum, Brass, Bronze, Carbon Steel, Cold Rolled Steel, Steel, Stainless Steel)

- Exotics: Hastelloy, Inconel, Monel, Molybdenum

- Plastics: Delrin, Nylon, Polyethylene, Teflon

Additional Machining Capabilities

Conventional Machining

- Turning

- Milling

- Grinding

- Drilling

- Tapping

Industries We Serve

We proudly serve a diverse range of industries, including:

- Electronics

- Construction

- Military

- Oil & Gas

- Pharmaceutical

- Sensors

- Trucking/Transportation

- Security & Safety

- Semiconductor

An Overview of Our Screw Machine Products and Services

The precision and expertise we have developed over the years, along with our proper tooling maintenance, are key factors contributing to the success of our screw machining products and their application in diverse industries. While stainless steel is the most common metal used for screws, we offer screw machining of various other metals.

Screw Machining Steel

We use low carbon content steel for increased ductility, specifically grades 303 and 316.

Screw Machining Aluminum

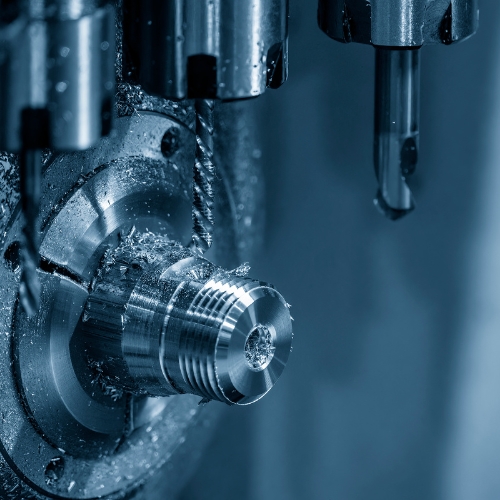

This is a high-speed process since aluminum is lightweight and offers high mechanical strength. Multiple spindles of our screw machines help shape the screw by running across the workpiece.

Screw Machining Brass

After steel, machining brass is quite common. We manufacture various screws and fixtures from this durable and lustrous metal.

Swiss Machined Parts

We offer Swiss machined parts with complex designs and intricate details for mission-critical applications such as medical screws used in orthopedic surgeries.

Some of Our Popular Screw Machined Products

We offer everything from prototypes to high-volume production runs. Our machines are capable of producing large quantities of screws with precision and tight tolerances as required. Our most popular screw machined products include various types of screws, nuts, bolts, fittings, fixtures, gears, shafts, pins, and more.

Why Partner with Princeton Industrial Products, Inc. for Your Quality Machine Parts

Customized Solutions

We take the time to understand your unique needs, ensuring the final product aligns perfectly with your requirements.

Experienced Team

With over 35 years of industry experience, our team handles even the most challenging projects with precision and expertise.

Advanced Technology

Utilizing the latest machinery and equipment, we guarantee accuracy and precision in every job we undertake.

Commitment to Quality

Our robust quality management system ensures all parts meet the highest industry standards.