Comprehensive Secondary Machining Services

Enhance Your CNC Machined Parts with Our Secondary Machining Operations

Secondary machining operations are processes or techniques generally performed on manufactured parts to improve their physical appearance or tolerances. In a CNC machining unit, the primary operation is to form or fabricate a part or component from sheet metal or plastic as per the required size and dimensions. This is done to fine-tune and smooth the surface finish. However, this is not enough, and final touches need to be given to the part or product. Secondary operations mainly comprise fine-tuning techniques such as polishing, surface finishing, coating, and so on. They also include testing and inspection techniques to check the functionality of the product or circuit boards. Princeton Industrial has an exclusive and efficient department that offers secondary operations for various types of CNC machine services. This helps us provide our customers with superior quality CNC machined and secondary treated parts.

Secondary Machining Capabilities

Almost all parts and components nowadays require secondary operations as part of either functioning or achieving a smooth finish, which helps in branding. Sometimes, it may be integral to the functioning, and if not done, the part may not function properly. For this reason, we closely monitor the operations of our secondary departments and suppliers. We have all the advanced secondary equipment and experienced staff, which helps us deliver parts with precision and within the stipulated timeframe. It helps boost productivity, brand value, and time to market of the OEM. Also, we offer all of this at competitive prices. Here are the secondary CNC machine services we offer

Plating

This is a method in which a thin layer of metal such as copper, silver, nickel, chromium, and so on is applied onto the substrate. This not only improves the aesthetics but also offers corrosion resistance.

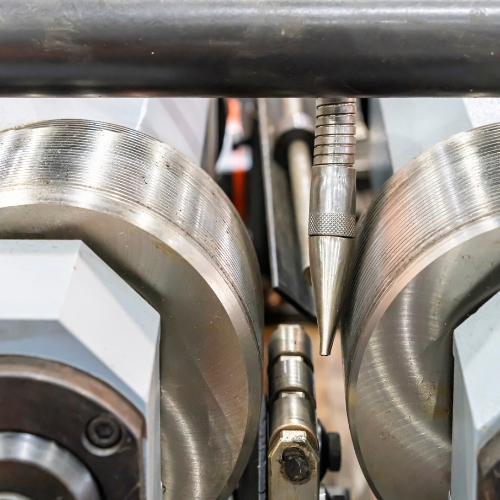

Grinding

This process removes the uneven and coarse particles and materials on the surface of the workpiece. It is done for fine-tuning and smooth surface finishing.

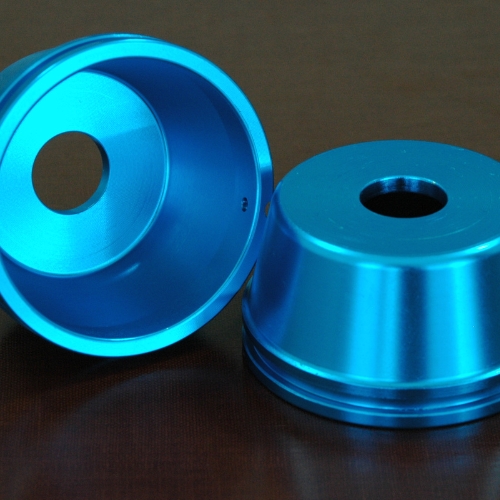

Anodizing

This is a process used to apply a thick oxide coating onto the workpiece surface. This makes the surface wear and corrosion resistant as well as improves aesthetics.

Part Identification

Our advanced machines, such as the milling and turning centers, feature a part-marking program that can be used to print markings on the part or product surface.

Heat Treating

Machined parts or components are heat treated either before or after the machining process. This is basically done to enhance their structural stability, strength, hardness, and other physical properties.

Polishing

The workpiece surface is polished after the machining process to remove coarse materials and burring marks.

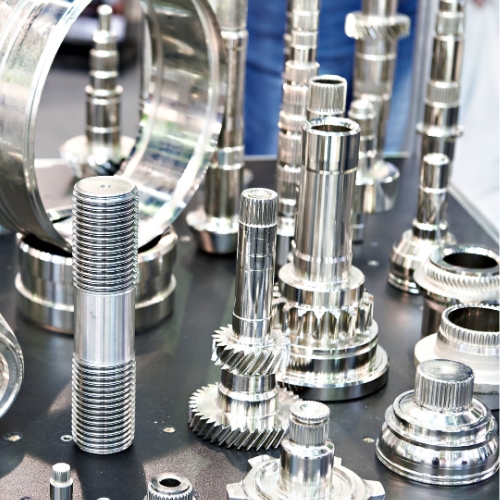

Casting Machining

Casting simplifies the process of forming a metal sheet into a part or product with tight tolerances, often within a few microns. While metal casting has been used for centuries, this is now a technologically automated process. It reduces the need to join too many parts, which in turn reduces resources and costs.

Thread Rolling

Here, a metal is rolled through dies to develop threads around the surface, such as in screws and many other fitting components.

Identification Stamping

In this process, letters of the logo or brand name product name are stamped into the metal workpiece. This is done through processes such as embossing, coining, or punching.

Laser Etching

Here, heat is generated onto the workpiece surface by focusing a laser beam, and layers from the surface are removed. The surface thus melts, and permanent marks are created onto it.

Contract Assembly

We offer services pertaining to the assembling process post-manufacturing a component. We have the required equipment and skilled workforce for the same.

Special Packaging

We offer services related to packaging and labeling of parts and products with special or specific requirements.

Benefits of Partnering with Princeton Industrial Products, Inc.

There are many benefits of partnering with us for your secondary machining operations

Quality-Centric Approach

Being a quality-centric organization, we are meticulous about the accuracy, precision, and quality we deliver in all our products. Also, All of this is delivered within established deadlines.

Comprehensive Services

We primarily offer CNC turning, milling, and other processes used to make CNC machined parts, and secondary operation is then a natural progression depending on the requirement. However, we also cater to secondary operations exclusively if that is the requirement.

Advanced Equipment

We have advanced machines with multiple axes, such as CNC machining centers, Swiss machining equipment, milling machines, and more.

Flexible Production Volumes

Volume is not an issue for us, and we can deliver high-volume production runs. Additionally, we also accept prototype and low-volume orders.

Material Expertise

We offer secondary operations on your cast, forged, and machined parts to enhance their functioning, precision, appearance, and quality. We offer these services for several types of metals such as steel, aluminum, and alloys.

Efficiency and Speed

Our processes help reduce waste and facilitate fast turnaround times.

Applications of Our Secondary Machining

Heat treatment is a common process performed on most parts and components as part of secondary operations. Here are some common application areas that take advantage of our secondary CNC machine services: